Sell your LCD’s offers a full refurbishment service for LCD displays from most up-to-date iPhone models to the older ones. For further details, see our current refurbishment list. If you've got an outsized number of spare working iPhone displays with broken glass, and you'd like better to have the choice to utilize them another time, why not send them to us for restoration? With the worth and quality of the service we provide , it makes cost efficient move, and therefore the final product is way better than basically any of the duplicate screens out there. The original Apple screens use “in-cell” technology i.e. the touch functionality is embedded on the LCD display itself, not on the glass. Often when the screen gets broken, it’s only the outer glass that’s cracked, and therefore the inner LCD display and touch functionality still function as normal. These original iPhone screens can therefore be refurbished by replacing the glass, which suggests you'll restore the upper quality of the first display which is above the aftermarket displays. It may be tempting to use Chinese copy screens in your IPhone. However, by refurbishing the first Apple iPhone LCD you'll charge more, have lesser returns, and have more control over the standard of your repair. Moreover, you don’t run the danger of an iOS update rendering your screen useless as went on within the past.

Preparing and Sending Your Screens

Completing the Form

If you'd wish to send us iPhone LCD screens to be refurbished then we request that you simply simply complete this sort. We will accept any iPhone LCD as long because the touch functionality and LCD are working. (Our process is predicated exclusively upon changing the glass- therefore, if the LCD is broken or the touch isn’t working correctly, we'll unfortunately need to reject it.)

Once your name and address details are completed you'll specify the number of every screen you're sending. If you'd like your screens refurbished in specific colors then please include this information within the “Other” box at the top of the shape.

Sending Your Screens to Us

Once the form has been completed and submitted, you'll receive a reproduction by email. Please print this off and include it in your package before sending it to us. It’s important that you simply pack the screens correctly to make sure a high success rate. (When the glass is broken on the screen it makes the LCD weak and it's extremely easy for the LCD to urge broken this way. So, you've got to take care about this.)

When We Receive Your Screens.

Initial Checks

When we receive your parcel, the primary thing we do is to count your screens to form sure the amount matches the number listed on the enclosed printout. Next, we test each screen and complete an intake form. When testing your screens the primary thing we check is to form sure we haven’t been sent any copy/aftermarket LCDs. (These are manufactured differently and can’t be refurbished.)

After this, we test each LCD to form sure it isn’t broken, the touch functionality is functioning correctly which there are not any damaged pixels or pressure marks visible on the screen. Pixel damage and pressure marks are the only commonest issue missed by people sending screens to us. Often, if your customer has been using the screen for an extended time while the glass has been cracked, the pressure will cause damage to the screen. Pressure damage normally shows itself as white, green, blue or red marks that are typically only noticeable on a dark screen. Often we'll test an order with the lights off to form sure that we will see the marks properly.

The Refurbishment Process

At this stage, if there is any issues alongside your order we'd usually contact you. However, assuming everything is so as, and then we'd start the refurbishing process.

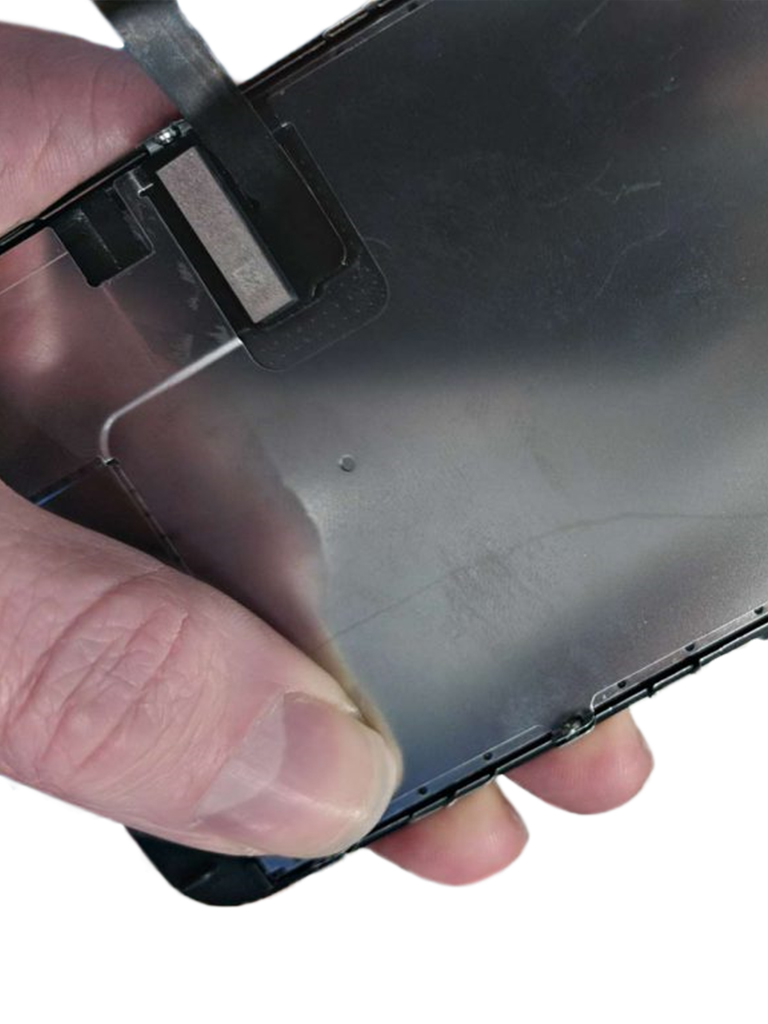

Removing the Glass and Polarizer

With Apple iPhone LCD displays we generally separate the screen using molybdenum cutting wire. This is often so we'll preserve the primary backlight. Once the glass has been removed we also remove the polarizer. Some refurbishers will plan to save the primary polarizer by using thinner wire to separate the glass. However, we always replace the polarizer, as often it gets scratched when the glass is broken, when the glass is being removed or once we clean the screen.

Installing the Replacement Glass and Polarizer

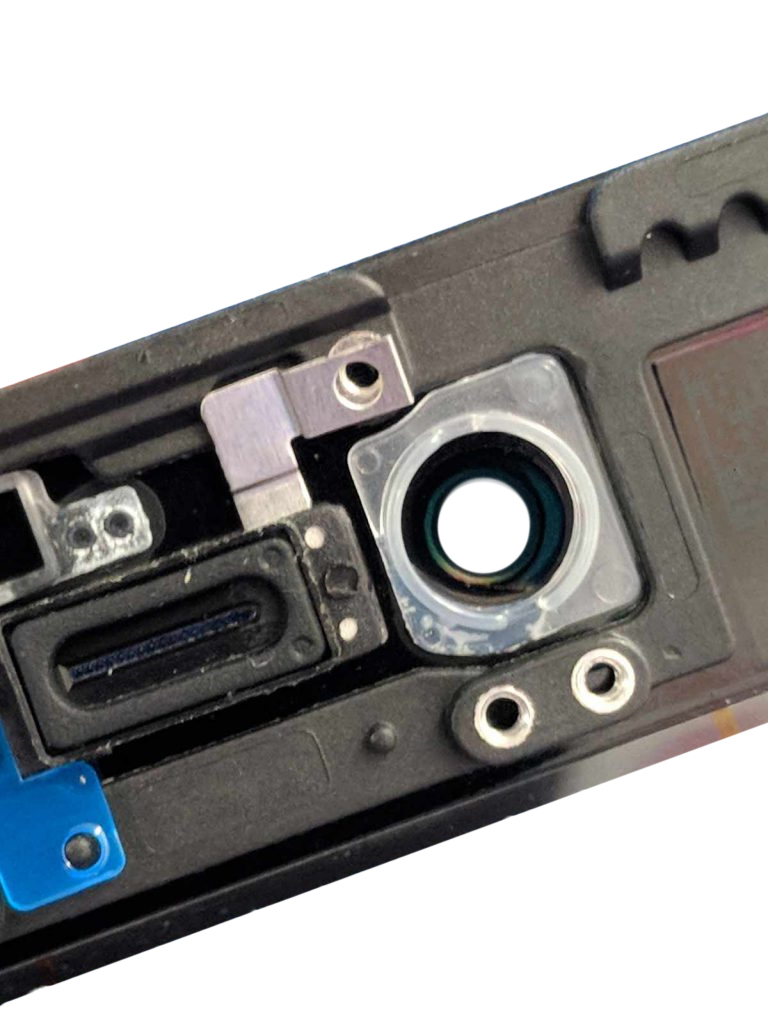

Once the screen has been cleaned we catch on ready for having the replacement glass installed. We only use as on the brink of original parts as possible for this process. The replacement polarizer, frame, and glass are original quality and therefore the frames are cold pressed so there's no risk of the screen lifting from the frame. The glass includes a rainbow tint on the camera lens and has an oleo phobic (grease-resistant) coating.

Final Stages

lastly, the iPhone LCD screen will advance to the last word stages of refurbishment where it'll receive the

finishing touches. This a part

of the method varies counting on the model of the LCD screen but generally, the primary thing we might do is check the house button is functioning.

On the iPhone 7, 7+ and each one

newer screens, we'll screw on a replacement back plate to protect the flex cable from

damage. On the 6S and later we include an adhesive seal. Our warranty sticker

is applied in conjunction

with backlight solder stickers, where required, and a replacement

backlight protection sticker is fitted.

The screen is then tested a final time to form sure that it’s working, before being packaged during a bubble bag able to be shipped to the customer.

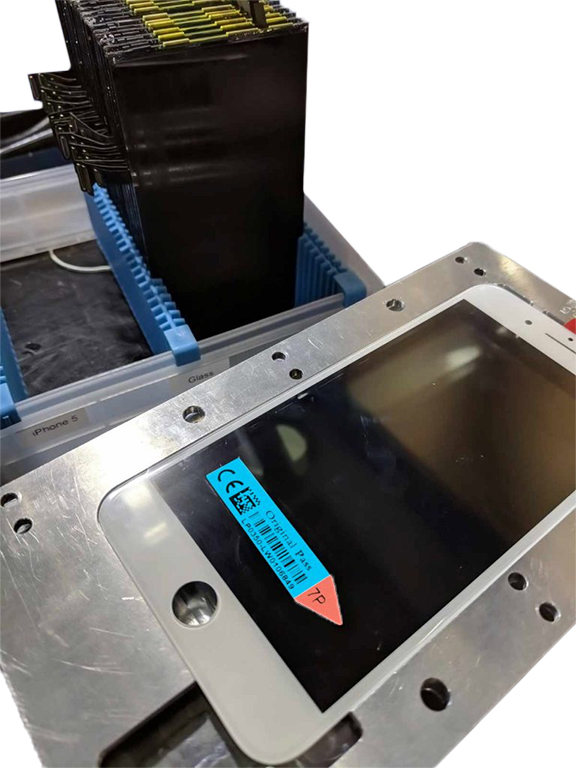

From left to right- The LCD inside the mould for installation of the replacement glass, a closeup of the rainbow tint on the lens glass, and the oleophobic coating in action.

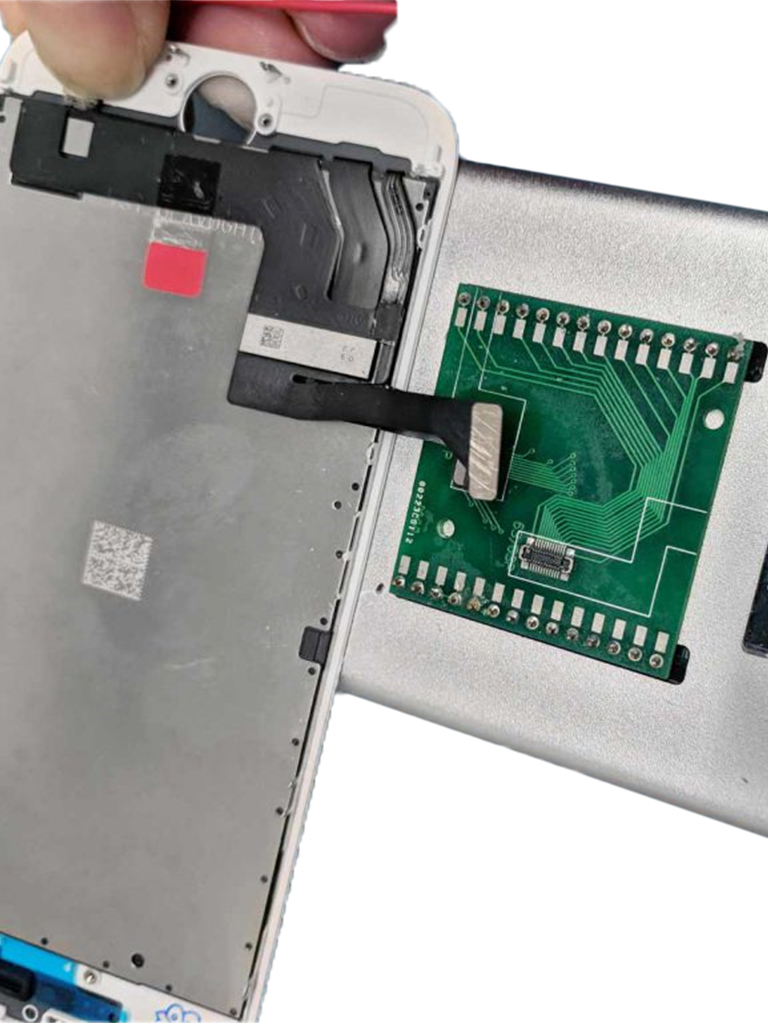

From left to right- Checking for touch issues, inspecting the backlight and looking for dust.

Checking the home button. Screwing on the back plate. Solder point sticker.

Attaching the warranty sticker. Red sticker attachment. The work completed, the display is now ready to be packed.

Completed screens ready to go into their bubble bags then boxed for safekeeping. Once boxed, the screens go out complete with the adhesive seal.

So, What are you waiting for? Fill out the refurbishment form now!